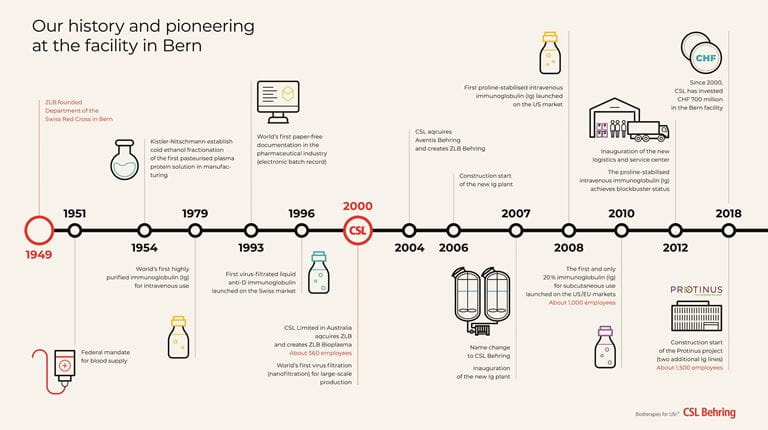

Our success story in the heart of Bern begins in 1949. Under the roof of the Swiss Red Cross, the first blood donation service in Switzerland is founded under the auspices of the Swiss Red Cross: the central laboratory of the Swiss Red Cross’s blood donation services (ZLB). Since then we have been processing blood plasma. The components of the yellowish, clear liquid portion of the blood has the potential to substantially improve the lives of thousands of patients.

Kistler and Nitschmann pave the way

Research and resulting improvements to plasma processing coin our company story. The researchers Hans Nitschmann and Peter Kistler developed a novel method for the fractionation of plasma: the Kistler-Nitschmann method. It increases the yield of protein isolation – immunoglobulins - from plasma. Immunoglobulins are proteins that the body produces to fight off foreign substances (so called antibodies).

The turn of the millennium has changed us

In 2000, the Australian CSL Limited acquires ZLB and in 2007, the company is rebranded to CSL Behring. At the time, 560 employees work at site Bern. The turn of the millennium is important for Manufacturing as well and we are the first company in the world to introduce nanofiltration (virus filtration) to large-scale manufacturing. With this, our company has globally raised the standard for immunoglobulin products.

Sustainable growth

Today, more than 1,600 employees work at CSL Behring in Bern. Construction for the building project Protinus started in 2018. The construction of the multi-story building includes two manufacturing lines. This capacity expansion will help about 90,000 more patients per year to live a normal life. The project is a challenge, as the high-tech facilities are constructed in the tightest of spaces and, therefore, require special structural measures. Additionally, the schedule for the project is tight: the CHF250m project started in 2017, we celebrated the foundation stone ceremony in 2018 and manufacturing is planned to start in 2021.

Clean energy from wastewater

In terms of growth, sustainability is of great importance to us and we accept our responsibility for the environment. We optimize the use of resources and minimize emissions with eco-friendly processes. For example, ara region bern ag produces clean energy from CSL Behring’s industrial wastewater since autumn 2018. This saves more than 1,700 tons of CO2. Additional reductions will be achieved by using recycled ethanol in manufacturing processes. Furthermore, we will be implementing comprehensive energy efficiency measures that will result in energy conservation of more than 6 gigawatt hours or 1,000 tons of CO2, respectively. Our growth shall be as sustainable as possible – for people and the environment.